|

|

|

|

HOME > INSPECTION > Definition of Defect HOME > INSPECTION > Definition of Defect |

|

Definition of Defect Definition of Defect |

Small Defect (Penalty point 1 point)

Defect within 2.5cm of warp direction and weft direction.

(Exclude holes and tears defect) |

|

Medium Defect (Penalty point 3~5 points)

Warp Direction : Within 2.5cm~12.5cm, 12.5cm~25cm

Weft Direction : Within 2.5cm~12.5cm, Within 12.5cm~1/2 Width

(Holes and tears defect, Within 1.5cm) |

Large Defect (Penalty point 10 points)

Warp Direction: Within 25cm~91.5cm

Weft Direction : over 1/2 of fabric width, full width

(Holes and tears defect, within 1.5cm~5cm) |

Free of Charge Defect

Warp Direction : Free of Charge disposal within 91.5~183cm

(However, more than 183cm Will be cut in principle) |

|

|

| |

Details of Content Details of Content |

| 1) Width : The width in the order sheet means such real width as can be cut except for selvedges of the both sides. |

| |

In case of fabrics without selvedge it means the real width except for pin marks on both edge.

In case uneven width is found in a fabric roll, the narrowest width shall be the standard width.

In case a width less than that described in the order sheet is found reprocessing shall be made of

consultation shall be made with the client.

Piece length conditions shall be implemented as specified in the order sheet. |

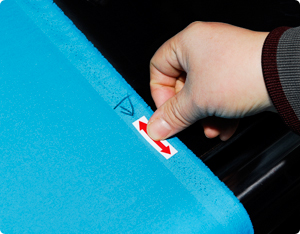

| 2) Length : The length means the distance from the both sides tape attached part at the end part of the paper pipe |

| |

(roll core) to the end mark. |

| 3) Color : It is impossible to specify the allowance limits of colors, and coloring shall be conducted in comparison with |

| |

the original color, and in case any color difference is found between lot, lot sample shall be presented to the client for confirmation, and then it shall be decided to ship such a lot or not.

Left and right listings shall be sewed in th order of 3, 1, 4 and 2 after each roll is cut, and left and right listings shall be checked. |

|

|

|